OUR FILTERING MATERIAL: PURE BIO

Natural bioactive supports consist of materials that naturally contain bacteria dispersed in the structure of the

medium itself, rather than as a distinct biofilm on the surface and within the pores. Some of the most common natural

supports are: soil, compost, peat, various types of wood.

Most natural media contain organic matter; the adsorption of contaminants on these materials occurs through many

physical-chemical processes, such as: van der Waals forces, H bonds, dipole-dipole interaction, ion exchange, covalent

bond, ligand exchange, and / or hydrophobic partition.

The absorption / adsorption (sorption) of the contaminant can be schematized as a combination of two mechanisms:

(1) hydrophobic partition from the aqueous phase (the contaminant is solubilized by the gas phase) and (2) adsorption

on the surface of the medium (phenomenon that tends to dominate when contaminants are present at low

concentrations).

Contaminants, once adsorbed in the organic fraction of natural supports, are subjected to a combination of abiotic

transformations (such as hydrolysis, chemical bonding, red-ox reactions, polymerization) which are often catalysed by

the metal oxides. Generally, biodegradation of pollutants can be obtained via aerobic and/or anaerobic processes,

depending on microbial population (e.g., heterotrophic and autotrophic bacteria, actinomycetes, fungi and protozoa)

which is stimulated.

Mass transfer of contaminants within the aggregates of the natural material affects the performance of the filter

support and it is dependent on the humidity of the support (i.e., filtering material). Under a critical water content, the

bioactivity of the medium is negligible and the medium loses its structure, creating cracks through which

contaminated air can by-pass the bed. Experiments reported in scientific literature have shown that there is an

“optimal” water content at which bioactivity is maximized; therefore, above and below this value the biodegradation

rate begins to decrease, mainly due to the mass transfer constraints caused by the water film that forms (or

disappears) outside the filling material. It is important to underline that the prolonged lack of water leads to the

irreversible loss of the original bioactivity of the filter medium (each natural filtering material has a specific water

retention capacity, function of intrinsic porosity, which in turn depends to the characteristics of the material used for).

Finally, natural media during their life are subject to breakage and compaction which, if not properly managed, lead to

channelling and to pressure drops in the filter bed.

In the light of what it has been briefly explained, it is clear that the identification of the appropriate filtering material

and its correct management and maintenance are fundamental elements for obtaining the

desired removal yields. Arte e Lavoro, based on you needs, can realize the appropriate filtering material; our flagship

filtering material is the so-called PURE BIO.

PURE BIO is a filtering material obtained from the mixing of woods (not composted, composted or mixed together)

able to guarantee the optimal environmental conditions for the proliferation of the microbial population necessary to

obtain an effective bio-removal process.

The materials used for obtaining the filtering mixture derive from the activities of mowing and pruning of the plants.

The production cycle changes according to the characteristics required for the filtering material (characteristics are

defined by our technicians); generally, woods essences are selected, screened and reduced in size (if required

screened again).

For more information download PURE BIO’s data sheet

Features

The main characteristics of PURE BIO are:

- high content of autochthonous microorganisms (such as, for example, actinomycetes, megaterium,

licheniformis, subtilis, yeasts and enzymes) - high porosity

- high content of macro and micro nutrients

- reduced pressure drops

- high removal yield for a wide range of pollutants (also without inoculation).

Thanks to these characteristics, PURE BIO can be effectively used for the removal of a wide spectrum of contaminants

(such as, for example, odours, VOCs, NH3, H2S, mercaptans). Furthermore, the high content of macro and micro

nutrients allows PURE BIO to manage any shocks due to sudden fluctuations in the feeding pollutants load.

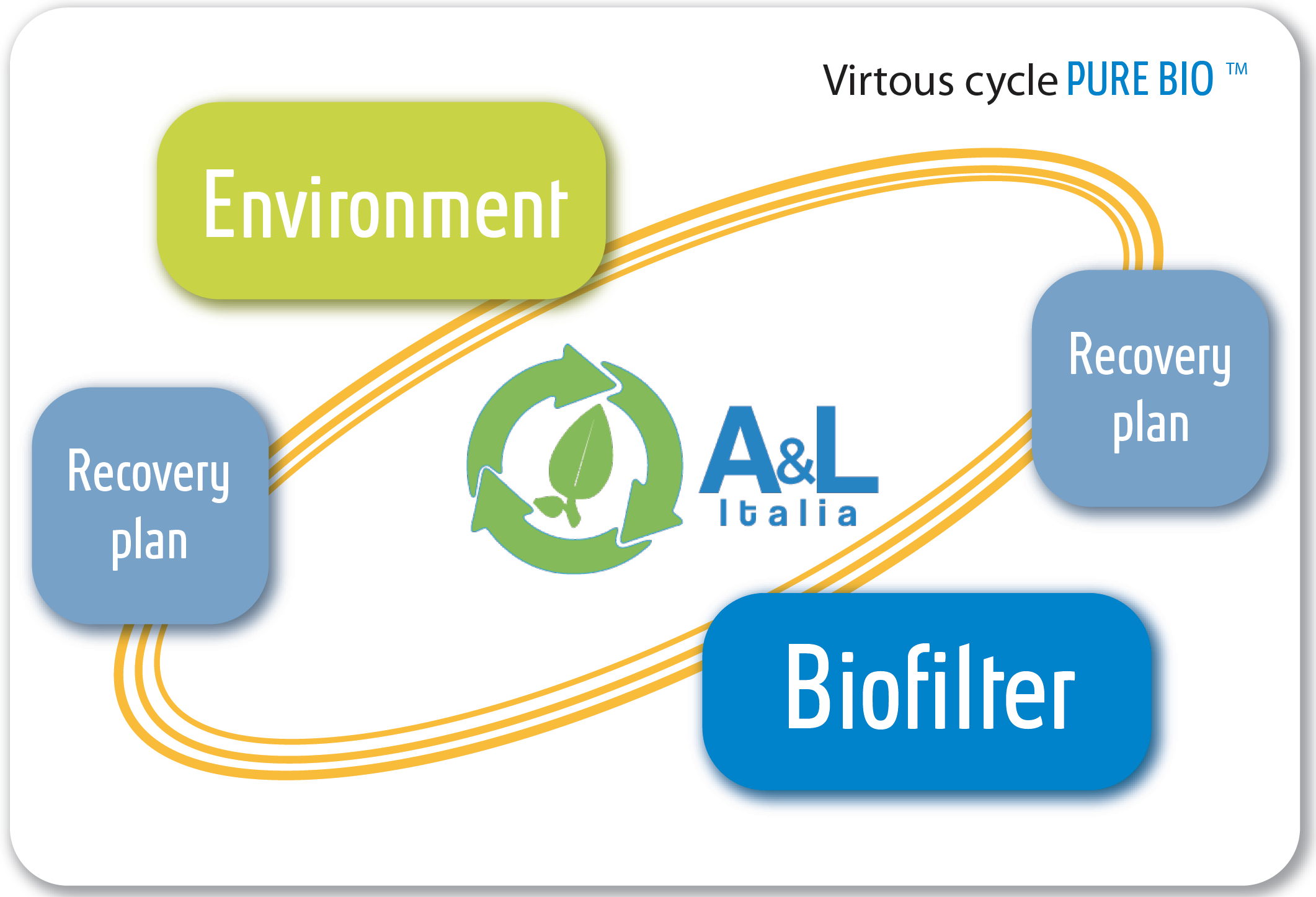

ENVIRONMENTAL FEATURES – the virtuous cycle of PURE BIO

An important environmental aspect associated with the use of PURE BIO is what we like to call the “virtuous cycle” of

the filtering material. This definition derives from the fact that, with rare exceptions, our filter material can be

considered a green material because it is able to comply with all the most recent regulatory indications on waste

management and circular economy.

Why do we speak about a “virtuous cycle”? The virtuous cycle starts at the origin of the process: basically, most of

the woods used for the preparation of PURE BIO derive from the activities of mowing and pruning of the plants and

not from deforestation activities. This allows to keep national forest resources unaltered and to limit CO2 emissions

due to their cutting and transporting. Green waste, which are normally treated in composting plants, are used for the

preparation of our filtering material. For the production, the green wastes are reduced in size and screened (according

with our requirements) and then transported to the plants, i.e., the plants where the biofilters are in operation. Once

the filtering material has ended its service life, it is delivered to the same plants from which they were originated,

where it is recovered by means of composting at the end of which it is reintroduced into the environment as compost

or filtering material. As you can see, the life cycle of PURE BIO is a closed (virtuous) cycle.

Other kinds of available filtering materials

- zeolites

- hestnut wood (available in different sizes)

- peat

- bark (available in different sizes)

- roots

- heather

- wood chip

- granular activated carbon (GAC)

Applications

PURE BIO is used in biofilters that treat contaminated air produced in solid/liquid waste treatment plants or

wastewater treatment plants (such as, for example, incinerators).

For more information download PURE BIO’s data sheet

@airqualitymaker.com

@airqualitymaker.com